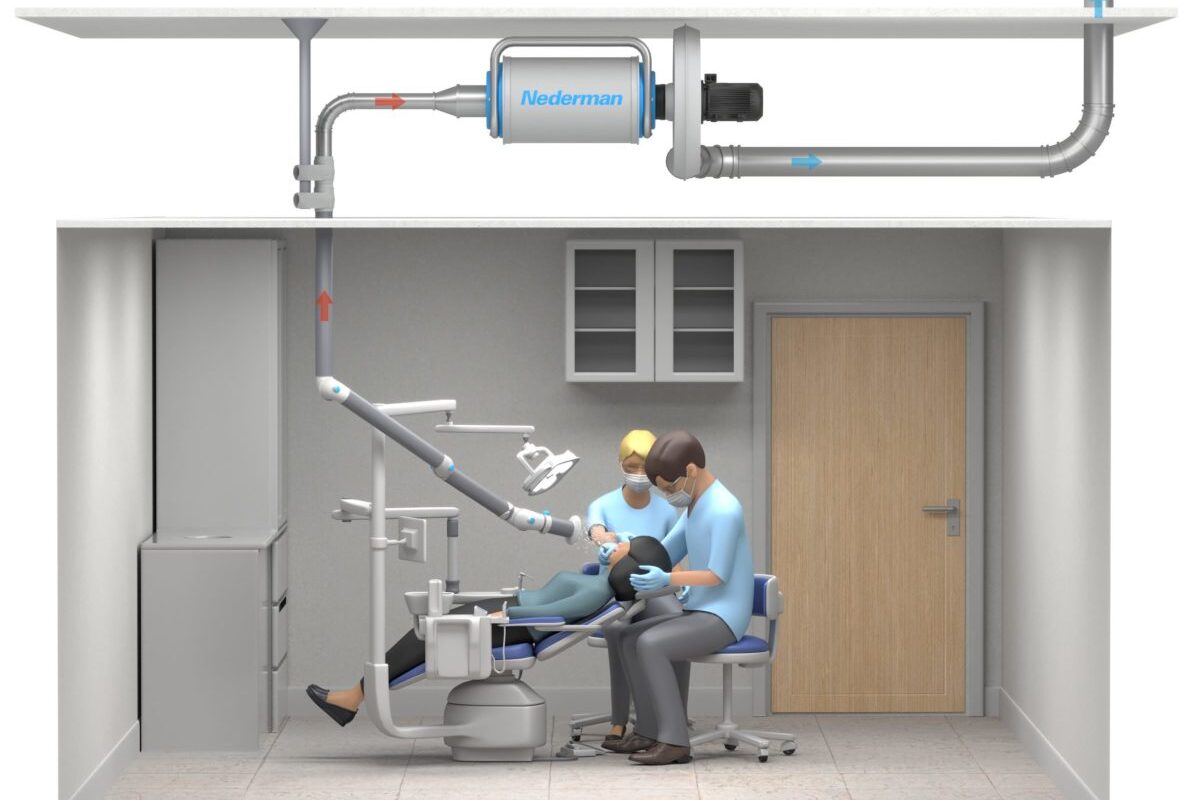

As we know well, long-term exposure to dust and fumes risks serious harm to staff as well as plant and machinery. At AtSource it’s our mission to provide engineered systems for clean air in your workplace.

Here, we outline the steps we take to ensure the best system for your needs, to minimise the health and safety risks to your people, plant and place.

Pre-Studies and Planning

Our process begins with a comprehensive visit to your facility or application site. During this visit, we thoroughly assess your needs, discuss specific requirements, and gather essential information. This initial phase is crucial to kick-starting an effective and tailored design process.

Design

Leveraging the power of Nederman’s PROQuote program, we deliver swift and professional proposals. Our team of seasoned engineers ensures that each design is not only efficient but also guaranteed to meet your project timeline. Our goal is to simplify your job by providing top-notch design services. Each industry must comply with various regulations, and each business has unique operating procedures. We take note of this and ensure that not only the system we design, but the process of installing it, will allow continuous efficiency in your business.

Selection

Combining our extensive experience with the capabilities of PROQuote, we meticulously select and recommend the most suitable products and solutions for your application. Our user-friendly and practical solutions are designed to meet your unique needs with precision.

Specification

Using PROQuote, we detail and schedule all necessary components, streamlining the process for you. This includes ducts, pipes, fittings, products, and any recommended accessories. We support our specifications with comprehensive technical leaflets and data sheets for all products, ensuring clarity and ease of implementation.

Supply

We pride ourselves on holding the largest range of dust and fume extraction products in New Zealand. Thanks to Nederman’s extensive manufacturing and distribution network, we can quickly source any item not in stock. As direct importers, we supply a wide array of mechanical contractors, wholesalers, and end users from our warehouses in Auckland and Christchurch.

Installation

Our installation services are executed by our dedicated staff and contracted teams, capable of handling projects of any scale. We monitor all installations to ensure they meet the highest quality standards and align with customer expectations.

Commissioning

With our extensive experience and advanced testing equipment, we ensure that all installations are executed flawlessly and that the equipment performs as intended and required.

Training

We offer comprehensive product and system training, which can be customized to your specific needs. This ensures you derive the maximum benefit from your equipment and systems.

Maintenance

To maintain optimal performance, we have robust systems and registers in place to support and track your assets throughout their lifecycle. Our service personnel regularly travel nationwide to perform annual service and maintenance programs for our key clients, ensuring your equipment remains in top condition.

From planning, to installation, to maintenance, our goal to achieve clean air in your workplace is thoroughly considered, with each system engineered to ensure the best results for health and safety for your staff and other business assets.

Get in touch with us to find out how we can achieve this in your business.