Spring in New Zealand has a reputation: sunshine one moment, sideways rain the next. For anyone working on-site, in workshops, or in industrial environments, that usually means one thing — wet gear.

At home, it’s easy enough to kick off soggy boots at the door and let them drip-dry overnight. But in a busy workplace, waterlogged boots, damp gloves, or a soaked jacket aren’t just uncomfortable — they can quickly become a genuine health and safety risk. And let’s be honest, no one wants to start their shift by stepping into yesterday’s damp socks or pulling on a clammy helmet.

The Reality of Wet Gear

In industrial and trade environments, wet protective equipment is more than just a nuisance. When boots, jackets, gloves, trousers, and helmets don’t dry properly between shifts, it creates risks that can affect both safety and productivity:

- Slips and trips are far more likely when workers track water from wet boots across floors.

- Hygiene issues build up quickly in damp PPE, where bacteria and mould thrive inside gloves, jackets, and helmets.

- Low morale sets in when staff are expected to get through a long day in wet or uncomfortable gear.

What seems like “just a bit of water” can snowball into absenteeism, reduced productivity, or even long-term occupational health concerns if left unchecked.

Drying Smarter, Not Harder

The traditional approach to drying PPE is to throw everything in a heated room and hope for the best — usually running heaters 24/7 to blast warm air into the space. The trouble is, this method is slow, energy-hungry, and often leaves boots and gloves damp on the inside.

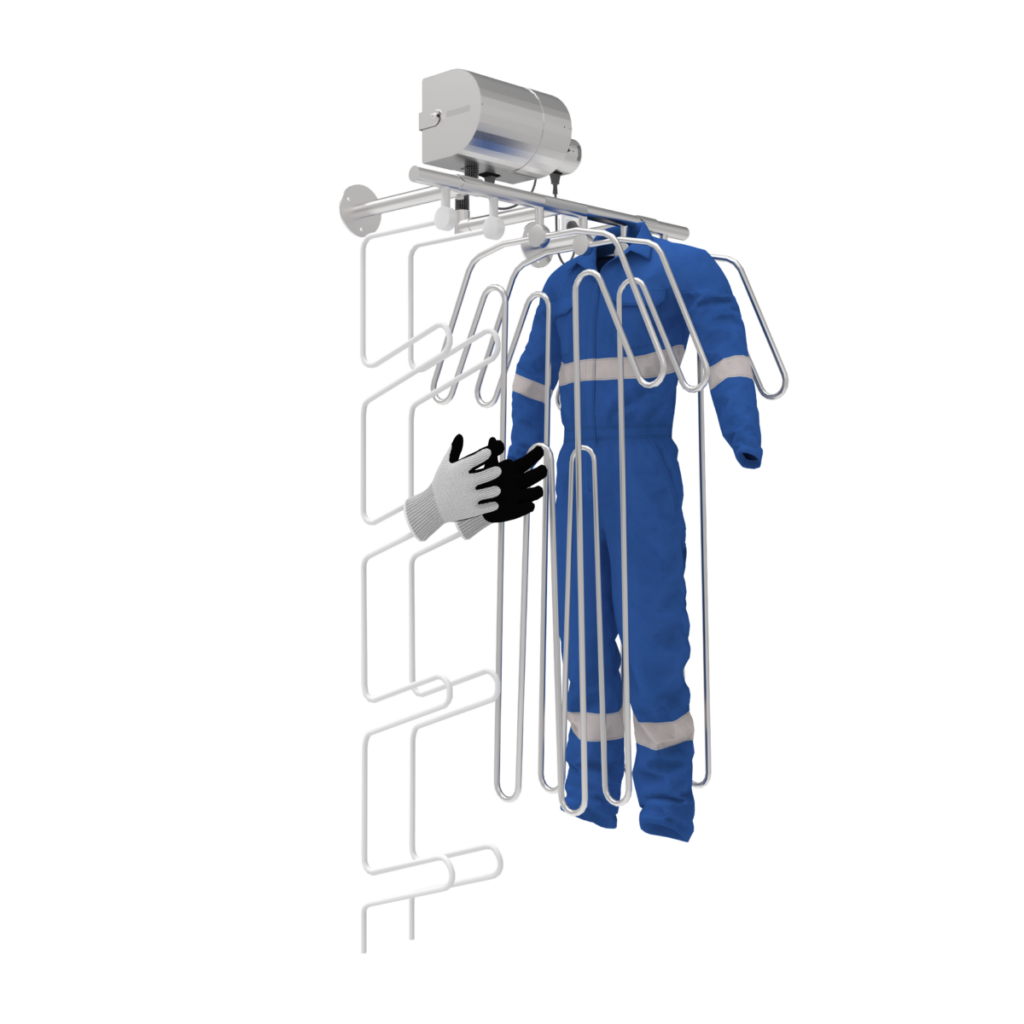

Modern PPE drying systems like the Pronomar range from AtSource work differently. Instead of heating a whole room, they push warm air directly into each garment — right into the toes of boots, the fingers of gloves, the lining of jackets, trousers, masks, or even helmets. That means thorough, even drying from the inside out, usually within just a few hours. No more half-dry boots, no musty gloves, and no wasted energy heating empty space.

What to Consider When Choosing a Drying System

Not every business has the same needs, so selecting the right system is important. Consider:

- The type and quantity of workwear your staff use daily.

- The space available in your workshop or facility. Drying systems come in a range of configurations to suit different layouts:

- Standalone drying cabinets are a neat all-in-one solution, keeping PPE secure, tidy, and protected.

- Wall-mounted systems make use of vertical space, ideal for workshops with limited floor area.

- Floor-standing racks can handle larger volumes of boots, jackets, gloves, and helmets — perfect for busy sites.

- Mobile drying racks offer flexibility, allowing equipment to be wheeled where it’s needed most.

- The specific drying requirements — whether it’s mainly boots and gloves, or full gear including jackets, trousers, helmets, and masks.

- Energy efficiency and performance — systems like Pronomar are designed to minimise energy use while maximising drying power.

AtSource can help you assess your requirements and recommend the right combination of drying systems to suit your space, workflow, and budget.

Dry Gear is a Win-Win

It’s easy to overlook, but investing in a proper PPE drying system can deliver long-term benefits. From healthier, more motivated staff to reduced downtime and extended PPE lifespan, the impact is felt across your entire operation.

Spring weather will always keep us guessing — but your team doesn’t need to face another day in damp boots or gloves. Get in touch with AtSource to find out how a tailored drying system can keep your workplace safe, efficient, and most importantly, dry.